S'pore builds stockpile of locally-made filters for reusable masks, for use only if pandemic worsens

SINGAPORE — Singapore is building up a stockpile of locally-made filters that add an extra layer of filtration to reusable masks, which will be distributed to the population only if the Covid-19 situation worsens, said Trade and Industry Minister Chan Chun Sing on Thursday (Jan 28).

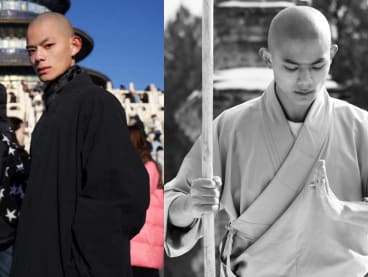

Trade and Industry Minister Chan Chun Sing inserting the filter produced by ST Engineering into a reusable face mask at the firm's Tuas facility on Jan 28, 2021.

Quiz of the week

How well do you know the news? Test your knowledge.

- Over recent months, ST Engineering imported machines to make filters that can be inserted into reusable face masks, to increase their protection

- Using the filters, reusable masks have protection equivalent to surgical masks, which can be reserved for healthcare workers

- These filters will be distributed only if the scientific community says Singaporeans need masks with higher protection

- Chan Chun Sing said if they are not needed for Covid-19, the filters will be stored for future pandemics or medical contingencies

SINGAPORE — Singapore is building up a stockpile of locally-made filters that add an extra layer of filtration to reusable masks, which will be distributed to the population only if the Covid-19 situation worsens, said Trade and Industry Minister Chan Chun Sing on Thursday (Jan 28).

Mr Chan added that these filters, made of a material known as melt-blown polypropylene, which provides the masks with protection equivalent to surgical grade masks while remaining breathable, will be distributed only if medical experts say Singaporeans need masks with higher protection.

“We have not reached that point and we hope that we never need to reach that point,” he said in response to TODAY’s question on how the Government will decide when the filters will be distributed.

Speaking to reporters after a visit to the Tuas plant of ST Engineering, where the filters are produced using machinery imported in recent months, Mr Chan said the filters will otherwise be stored for future pandemics or medical contingencies.

With the pandemic still raging around the world and the virus mutating into many forms, Mr Chan added that the Government is building this stockpile ahead of time.

Melt-blown polypropylene, a non-woven fabric that enables a high level filtration, is washable, commonly found in N95 masks, and has been widely recommended as the material of choice for face masks.

Mr Chan said in the last year, the machines to make the filters have been imported from around the world.

Studies have also been done to produce high-quality melt-blown polypropylene filters that are “much lighter, more breathable and yet have much higher filtration” than others on the market.

This move was spurred by the global supply crunch in face masks at the start of the coronavirus pandemic last year.

Although Singapore had the capability to produce sufficient surgical masks for healthcare workers then, the filters still needed to be imported, Mr Chan noted.

Now that the filters can be produced locally, there is no need to produce surgical masks for the population at large as the filters inserted into reusable masks can give the same amount of protection, he said.

This allows surgical masks produced here to be reserved for healthcare workers, added Mr Chan, giving greater assurance that both workers in healthcare settings and the rest of the population will be provided for in a sustainable manner.

He said this also ensures Singapore is “never held to ransom” by supply chain vagaries.

TWO FILTERS PER PERSON PRODUCED EACH WEEK

Mr Chan said Singapore now has the capacity to produce two filters per person each week. Each filter can last for three days or so, he added.

He said so long as Singapore can obtain the raw materials needed to make the filters, which are acquired from various sources worldwide, these filters can be produced locally.

In time, such materials will perhaps be acquired from speciality chemical plants in Jurong Island, he added.

Asked if the filters will be exported to other countries or used solely for domestic consumption, Mr Chan said this capability opens up new market opportunities, adding that the production team is looking into the use of the material for other commercial purposes, such as water filters.

“This filtration capability is not just limited in its use of the masks. In fact, there are many other adjacent products that can use such filtration, including some of the water filters that the industries use.

“So this investment will allow us to branch out to new markets and new products even if one day the demand for masks is reduced,” he added.

Temasek Holdings chief executive officer Ho Ching on Thursday took to Facebook to highlight the development. ST Engineering is part of Temasek’s stable of companies.

Madam Ho, who is the wife of Prime Minister Lee Hsien Loong, said Singapore had trouble getting good quality melt-blown polypropylene filters last year and several batches of filter material that arrived from different countries that arrived were not up to standard.

She said one of the machines to make the filters was flown into Singapore in parts, while a second machine was shipped in huge crates in several pieces.

Space for the machines had to be found, and engineers were flown in, served quarantine and set to work on the filter production process, she said.

“Not only could we produce our own to the specifications and standards we want, we could also experiment and research to make better filters,” she said, adding that the ones produced here have exceeded the standards for medical grade filters.

Mdm Ho said the ST Engineering team is looking into bringing the product into the market “soon”. The large size filters fit most adults while the medium-sized filters fit adults with smaller faces and children.